Plastic processing forums for extrusion information and advice and for other feed screw applications. Extrusion line should be equipped with an air hood located close to the die to take off vapors evaporating from melt leaving the die.

Ldpe Blown Film Waxs As A Function Of Their Draw Down Ratio And Corres Download Scientific Diagram

Multivariate Data Analysis X variables.

. But in practice the extrudate swell is smaller than the equilibrium value and some pulling is needed. After using the Draw Down Calculator below you can Request a Quotation or contact Guill to discuss how. This should be 20 to 1 or less.

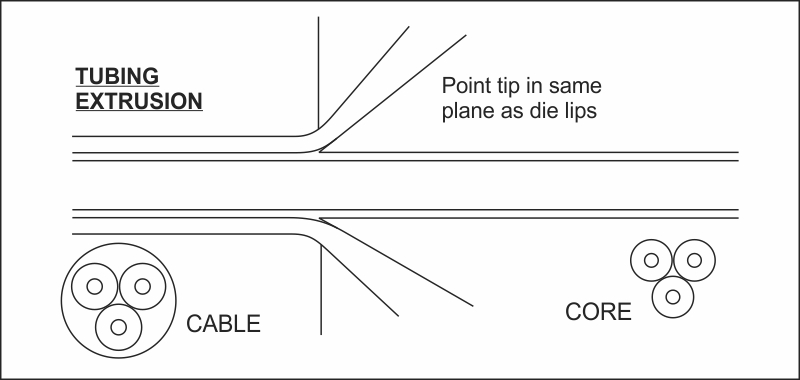

Tubing Double taper designs are preferred. Extrusion Parameters Parameters include die angle a extrusion speed billet temperature and lubrication Extrusion ratio R A o A f typical values of 10 to 100 Circumscribing Diameter CCD for Aluminum 6 mm to 1 m for steel up to 015 m Shape factor PerimeterCCD Extrusion constant k Typical lengths 75 m. Guill Tool Engineerings Tips and Dies are manufactured with precision unmatched in the industry today.

G and η 0 Response Y. The high quality of our extrusion tooling enables your company to output the highest quality product. This can also be referred to as the area draw ratio ADR.

In making sheet or cast film where the sheet width is nearly equal to the width of the die opening the ratio of the thickness of the die opening to that of the final sheet is sometimes spoken of as the drawdown ratio. Almost equal to DDR. Draw-down ratio DDR in a circular die such as a wire die is the ratio of the cross sectional area of the die orificeopening to the final extruded shape.

Up to 10 cash back Drawdown ratio. Pilot extrusion coating trials LDPE. For a tube this is calculated by the following formula.

The calculators below allow you to calculate DDR draw Down Ratio and DBR Draw Balance Ratios for a given Tip Outer Diameter OD Die Outer Diameter OD and finished product OD and ID Inner Diameter. The DDR is the ratio of the annular toolset exit area bushing ID area minus mandrel OD area divided by the final product area OD area minus ID area. In most extruders it is somewhere around 100 rpm.

In absence of a pulling force on the profile the ratio Lambda should approach 1. To keep the drawdown to a minimum. Draw Down Ratio - Plastic processing forums for extrusion information and advice and for other feed screw applications.

Shawn8791 Senior Member. 9 Frombrazil IN USA Registered. Plastic melt to the cross sectional area of the plastic in its final product form be it a tube hose or insulation on a core such as a wire or cable.

One exception to this is the twin-screw extruder used for rigid PVC pipe and profiles and lately for PET sheet and other resins as well. Draw Down Ratio is the ratio of the cross sectional area of the extruded. I currently extrude PE on a single screw extruder and use a Draw Down Ratio of 2 for tube covers and 339 for tube linersIDs range approx 63mm to 254mm and avg wall thickness is 2mm.

Simply provide these four values and calculate. R2 076 Q2 072 A linear relationship between neck-in and draw-down was also found 105 3635 375 118 5565 290. In this case it can be dried in a dehumidifying drier.

In the near future I want to extrude Polypropylene and wondred if. If deckles are used the internal flow channels should be streamlined so there is no stagnant TPU that would result in degradation. Previous results are saved and redisplayed so you can easily make adjustments and fine tune your solution.

Top screw speed is the top motor speed divided by the reduction ratio which is determined by the gear box and sometimes pulley sets. BUR blow up ratio. Draw down ratios of no greater than 151 is recommended.

68 - 89 g10 min. This difference may be desirable in tear tapes or strapping but unwanted if it reduces impact strength or shrinks differentially when cooling. 918 - 920 kgm3 Melt temperature.

Use the BH DDRDRB Calculator to calculate the Draw Down Ratio and Draw Ratio Balance of your current tool set and the BH Tooling Calculator to determine the optimal Tip and Die sizes for a new product or application. Draw-down DD Quality factors obtained. Draw down ratio DDR mean diameter of die gap divided by mean diameter of tubing.

Certain extrusion ratios reduce p to a minimum value and for the backwards extrusion of canisters A 0 A 2 is a desirable ratio for this reason. The subscript z refers to the diameter measured optically at a distance z from the die exit. Extent to which the plastic has been reduced in.

In extrusion of fiber spinning the ratio of the cross-sectional area of the die opening to that of the finished product. Another guide for setting uniformity and best repeatable references is the draw ratio balance DRB that aids in determining the minimum and maximum values that can be used for different plastics. 2 45 DDR draw down ratio gap widththickness x BuR MD machine direction TD transverse direction LD ratio of screw.

Generally for canisters a greater reduction can be effected by a forward extrusion than by a backward extrusion. Two important calculations involve the draw down ratio DDR and the draw ratio balance DRB. DD Diameter of Extrusion Die DT Outside Diameter of Tip PD Product Diameter CD Core Diameter The Draw Down Ratio DDR is calculated by comparing the cross sectional area of the extrusion.

Processing conditions Drying Generally not necessary unless the material is exposed to the atmosphere for a long period of time. Extrusion Tooling Tips Dies. Posted February 01 2008 1229 AM Does anyone have suggestions for draw-down ratios for small dia 125-1 fpvc.

Wall thickness ratio WTR die gap width divided by tubing wall thickness. Ing for the perpendicular extrusion angle Kistler and Scriven11 calculated apparent contact angles dependent on both Reynolds number and the drawdown ratio VsV0. Specifically for viscous curtains they calculate the fol-lowing scaling 03 0 s V V Re 2 for fixed apparent contact angles exceeding 160.

In extrusion there is always a machine direction and anisotropy shows up as MDTD difference or ratio in the final product in tensile strength elongation to yield andor modulus rigidity. Profile draw-down ratio. DDR DD2 DT2PD2 CD2 The Draw Ratio Balance DRB is the balance between.

The Effects Of Blow Up Ratio A And Draw Down Ratio B To The Download Scientific Diagram

Ldpe Blown Film Waxs As A Function Of Their Draw Down Ratio And Corres Download Scientific Diagram

Ldpe Blown Film Waxs As A Function Of Their Draw Down Ratio And Corres Download Scientific Diagram

Fundamentals Of Extrusion Technology Wire Cable India

Ldpe Blown Film Waxs As A Function Of Their Draw Down Ratio And Corres Download Scientific Diagram

0 comments

Post a Comment